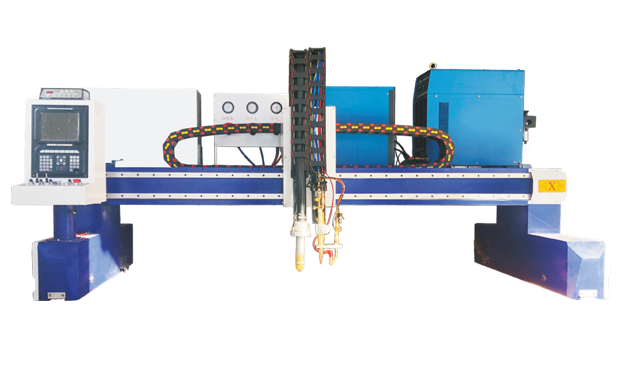

数控等离子火焰切割机

-

设备特点(Equipment Characteristics):该机型采用钢板焊接成型,坚固牢用;可切割中厚板;具有可数控编程,能切割复杂图形,可快速定位,加工效率高等特点。横梁及端架均采用钢板焊接成形,其具有刚性好,精度重,运行稳定且快速;该款机型采用数控电机双边驱动,线性导轨导向,界面简单容易操作,适合中厚板批量切割。广泛应用于钢结构,机械加工,汽车制造,钢铁贸易开料等行业。The model adopts steel plate welding forming, which is solid and firm; Cutting of medium and thick plates; It is characterized by numerical control programming, cutting of complex graphics, fast positioning and high processing efficiencyThe cross beam and end frame are welded and formed by steel plates, with good rigidity, heavy precision, stable and fast operationThis model adopts numerical control motor bilateral drive, linear guide rail guide, simple interface and easy operation, suitable for batch cutting of medium and heavy plate.

-

轨距(mm)Track gauge3000/3500/4000轨长(mm)Rail length可根据用户要求配置Can be configured according to user requirements横向有效行程(mm)Lateral effective travel轨距-600mmTrack gauge-600mm纵向有效行程(mm)Longitudinal effective stroke (mm)轨长-1500mmRail length-1500 mm割矩组数(mm)Number of cutting moment groups (mm)可根据用户要求配置Canbe configured according to user requirements火焰切割速度(mm/min)Flame cutting speed (mm/min)

50-750 等离子切割速度(mm/min)Plasma cutting speed (mm/min)视等离子电源型号而定Depending on the plasma power supply model空程速度(mm/min)Air travel speed (mm/min)10000割矩升降行程(mm)Cutting torque lifting stroke (mm)170/200 火焰切割厚度(mm)Flame cutting thickness (mm)6-100 等离子切割厚度(mm)Plasma cutting thickness (mm)视等离子电源型号而定Depends on plasma power supply model注:工作幅面可根据客户要求而定制(Customizable Working Format) -

镭山激光智能装备(佛山)有限公司

镭山激光智能装备(佛山)有限公司